If you rely on a diesel generator, whether for your business, home, or a remote job site, you already know how important it is to keep it running smoothly. Diesel generators are hardworking machines that provide power when and where you need it most, but like any engine, they need the right care to perform reliably.

When a generator goes down, it’s more than just an inconvenience; it can bring everything to a halt. That’s why understanding the basics of diesel generator maintenance and repair is essential. And the good news? With the right approach and the right support, you can keep your generator in top shape for years to come.

Why Diesel Generators Need Regular Care

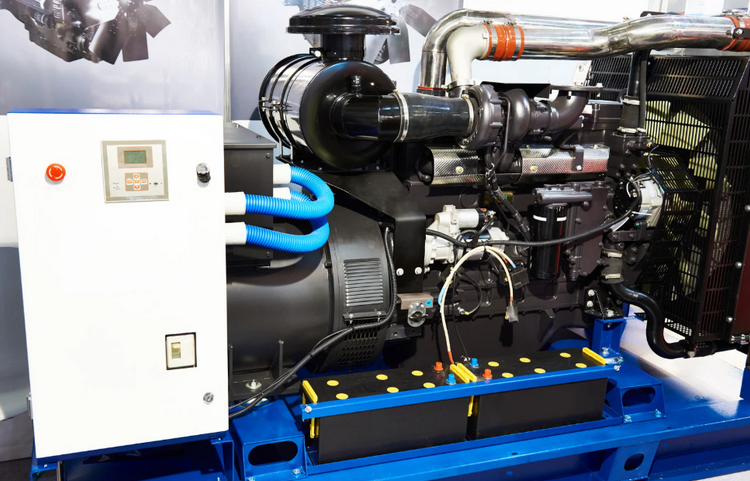

Diesel generators are designed for durability and power, but they aren’t immune to wear and tear. Over time, parts like injectors, filters, and electrical starters can wear out or clog, reducing performance or causing breakdowns. Dust, moisture, fuel contaminants, and extreme weather can all add to the stress.

Regular diesel generator services help you catch small issues before they become big problems. It’s like going to the doctor for a check-up. Routine maintenance keeps everything running smoothly and can significantly extend the life of your equipment.

Important Areas to Watch

Here are a few essential areas to keep an eye on when it comes to diesel generator maintenance:

1. Fuel System

Diesel fuel can degrade over time or become contaminated with water or sludge. Fuel filters and injectors can clog up, leading to poor performance or no start at all. Regular filter changes and fuel system inspections are a must.

2. Oil and Lubrication

Like any engine, your generator needs clean oil to reduce friction and wear. Dirty oil can damage engine components, so regular oil changes based on your usage hours are critical.

3. Electrical Starters

The electrical starter is what gets the whole system going. If it fails, your generator won’t start when you need it most. Make sure your starter system, battery, and wiring are in good condition and replace parts before they give up.

4. Cooling System

Diesel engines get hot, and without proper cooling, they can overheat quickly. Coolant levels, radiator condition, and fan belts should all be checked regularly to prevent breakdowns.

5. Air Filters

Clean air is essential for combustion. Clogged air filters reduce efficiency and can even lead to engine damage. These should be checked and replaced as needed, especially in dusty environments.

Onsite vs Offsite Services

Depending on your setup, you may need either onsite repairs or offsite services. Onsite services are especially useful for large or stationary units where transporting the generator isn’t practical. Technicians can come to you to diagnose and repair issues quickly, minimizing downtime.

Offsite services, on the other hand, may be more suitable for smaller units or more intensive repairs. Either way, having a team you can trust to provide both options is a big advantage.

Reliability Starts with a Service Partner You Can Trust

When it comes to diesel generators, reliability isn’t a luxury, it’s a necessity. Whether you’re powering a remote farm, a construction site, or emergency backup systems for a business, you need to know your generator will perform when called upon.

AMCS offers expert diesel generator services, including everything from routine maintenance to onsite repairs, injector replacements, and electrical starter troubleshooting. With years of experience and a team of qualified technicians, they ensure your generator runs efficiently and reliably, no matter the weather or workload.

Whether it’s a quick inspection, a major repair, or a scheduled service plan, AMCS brings the knowledge and tools right to your door. They understand the importance of uptime and offer fast, efficient solutions to keep your power supply running without interruption.